Key Features:

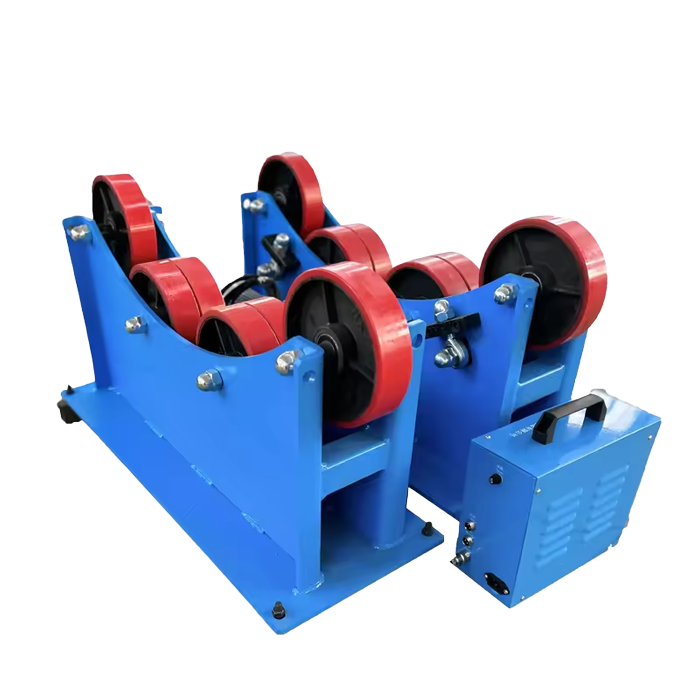

- Self-aligning or conventional types available to suit different workpiece diameters

- Polyurethane or rubber rollers provide stable support with high wear resistance

- Frequency inverter control system for stepless speed adjustment

- Remote control box and/or foot pedal for safe, user-friendly operation

- Heavy-duty steel frame structure for long-term durability

- Can be integrated with welding manipulators and positioners for automated systems

| Model | Load Capacity (tons) | Workpiece Diameter (mm) | Roller Diameter (mm) | Roller Width (mm) | Rotation Speed (m/min) | Motor Power (kW) | Roller Material |

|---|---|---|---|---|---|---|---|

| HGK-5 | 5 | 250–2800 | 250 | 100 | 0.1–1.0 | 2×0.37 | PU / Rubber |

| HGK-10 | 10 | 300–3200 | 300 | 120 | 0.1–1.0 | 2×0.55 | PU / Rubber |

| HGK-20 | 20 | 400–3500 | 350 | 140 | 0.1–1.0 | 2×0.75 | PU / Rubber |

| HGK-40 | 40 | 500–4500 | 400 | 160 | 0.1–1.0 | 2×1.5 | PU / Rubber |

| HGK-60 | 60 | 600–5000 | 450 | 180 | 0.05–0.5 | 2×2.2 | PU / Rubber |

| HGK-100 | 100 | 800–5500 | 500 | 200 | 0.05–0.5 | 2×3.0 | Steel / PU Option |

Reviews

There are no reviews yet.